The Rosendale Cement Industry

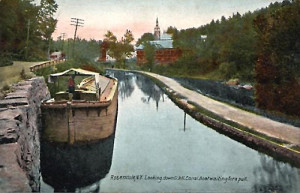

1825 was a momentous year for that stretch of land between the Catskills and Shawangunks that would soon become the D&H Canal corridor. In that year, on the Summit section, the first shovelful of dirt was turned in the vicinity of present-day Wurtsboro to begin construction of the canal.

Further north in Rosendale, 1825 also witnessed a significant event. While excavating the canal bed a large deposit of limestone was uncovered that would soon become the foundation of the Rosendale natural cement industry. Though the discovery was fortuitous, the canal company was certainly searching for local sources of cement and quickly took advantage of the find.

The initial design for the D&H Canal called for 108 locks as well as numerous aqueducts and bridges. All would require cement for their construction. Until the discovery at Rosendale, it was expected that cement would need to be brought in from various distant sources along the Erie Canal. To reduce the cost of transporting cement to the work sites the canal company employed a geologist who was specifically engaged to find and identify any local sources of hydraulic cement.

Almost from the very start, the D&H Canal had competition from other canals in supplying New York City with anthracite coal. In response, it embarked on an almost continuous series of canal enlargements through the 1850’s that allowed it to carry larger and larger boats. This had the effect of lowering the unit cost for transporting coal on the D&H. The cheaper Rosendale cement helped make these enlargements affordable.

The limestone deposits that were discovered in Rosendale were huge, being 22 feet deep, three miles wide and extending over seven miles towards Kingston. Eventually, there were 15 giant cement mills in the area producing millions of barrels of cement a year.

Rosendale cement was the most famous cement of its day and was the benchmark for all other natural cements. Between 1870 and 1872, Rosendale cement was used in building the piers for the Brooklyn Bridge. These massive 45 and 78-foot deep foundations were built of solid concrete. The 276-foot masonry towers also used mortar made of Rosendale cement. The towers took three more years to complete and were higher than New York’s tallest office building at the time.

From 1884 to 1886 Rosendale cement from the Widow Jane mine was carried on the D&H Canal thence down the Hudson River to Liberty Island where it was used to construct the base for the Statue of Liberty. This was the largest 19th century concrete structure in the United States. The pedestal foundation extends to a depth of 20 feet and is almost all solid concrete. Massive concrete walls 8 to 19 feet thick back the granite walls of the pedestal.

D&H Canal coal was important to the 19th century construction industry. It fueled the Rosendale cement kilns and was a key ingredient in the clay mix used by the Hudson Valley brickyards. These two industries complimented one another. Rosendale cement was an excellent material for the mortar used with Hudson River bricks and didn’t compete with brick construction because it wasn’t good for large concrete castings. It had a slow chemical reaction, set slowly and was prone to shrinkage cracks in large castings because of its evaporative drying.

In 1871, Portland cement technology finally came to the United States. Limestone deposits discovered in the Lehigh Valley of eastern Pennsylvania proved conducive to manufacturing Portland cement. By 1900, the Hudson Valley also had two operating Portland plants. Portland cement set very rapidly and was soon preferred over Rosendale cement for mortar. Cast concrete also didn’t have time to develop shrinkage cracks and, when used with steel framing, became a viable substitute for brick and mortar construction.

Portland cement had a significant impact on the Rosendale cement market. From 1900 to 1910, natural cement production across the United States plummeted from about 10 million barrels annually to one million while Portland cement production grew from one million barrels in 1895 to over 12 million by 1910.

The D&H Canal was critical in establishing and sustaining the Rosendale cement industry. In turn, New York City was the impetus behind building the canal in the first place. The city’s growth required that it reach out to its hinterland for a continuing supply of building materials. During the 19th century a steady flow of wood, bricks, cement and bluestone was carried down the Hudson to the city alongside the coal that would be used to heat the growing metropolis. In a sense there was a pipeline from the sources of New York’s key commodities to the city itself. The city helped foster these industries and provided a market for them.

The industries the canal helped spawn eventually came to overshadow the canal itself. The Rosendale cement industry is a prime example. When the canal was finally shut down in 1898 the section from Rosendale to the canal’s terminus at Eddyville was kept open until 1913 in order to carry cement to the Hudson River boats. In this regard it was the cement industry that in the end supported the canal and not vice versa.

To learn more about the story of the Rosendale cement industry Footsteps Across Cement by Ann Gilchrist is a valuable resource. The book is available at either the Ellenville or Rosendale Libraries. Also of interest is Stories of Rosendale by Walter Williams available from Williams Lake in Rosendale. The Century House Historical Society in Rosendale is also a very worthwhile resource.

Copyright 2006 by Stephen Skye

Short Link: