The Life of a Brakeman

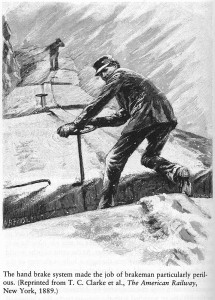

In the early days of railroading the brakeman’s lot was fertile ground for legends and poems. The railroading journals were full of odes entitled “Only a Brakeman”. One example is a poem of that title which appeared in Locomotive Engineers Journal in 1885. The job of the freight train brakeman was a solitary one and was especially dangerous. Before the widespread use of airbrakes in the late 19th century, trains were stopped through the manual application of brakes on each of the train’s cars. Even after the airbrake came into universal use, the brakeman still had to be ready to climb atop the train to manually set the brakes when the airbrakes failed to work or when a section of cars had to be cut from the train. In the interest of train safety, the middle brakeman, if there was one, would ride out in the open in order to be ready to manually apply the brakes if the need arose. Middle brakemen were most frequently used on long freight trains as well as on local freight lines where freight cars had to be cut loose or added on regularly.

To apply the brakes, the brakeman would turn a large brake control wheel located atop each freight car of the train. Every brakeman carried a thick brake “club” to help give them leverage in turning the wheel. This meant that they would have to run along the top of the railway cars and leap from one to another in order to apply or release the brakes on each car. Generally, the rear brakeman, or flagman as he was also known, would advance from the end of the train whilst the head brakeman or the conductor would advance from the engine to apply the brakes on each car, one by one. On a moving train, especially in bad weather, the application of brakes was a risky proposition, at best. Worse still, a stuck brake wheel might suddenly free up and throw the brakeman off balance. All too often this would result in the brakeman falling between the cars to his death. Riding in the open, frequently exposed to the bitter cold of winter, the brakeman’s job was fraught with danger.

Running across freight car roofs to engage the brakes on each car as quickly as possible was a hazardous affair. In winter the planks atop the freight cars would be slippery with ice and snow. Furthermore, tracks were not always aligned horizontally resulting a rolling motion as the cars passed over uneven areas of track. At a height of 12 or 14 feet above the track grade, the rolling was much magnified and posed a grave danger to the unlucky brakeman riding atop the freight car. In the worst case, the brakeman would be thrown to his death underneath the wheels of the train.

The O&W railroad tunnel at High View was the first of three tunnels to pierce the Shawangunk Mountains. It was unlined and unvented. The Shawangunk Grit that the tunnel was bored through was prone to fissures, cracks and rock falls. This required almost daily inspections of the tunnel. In the days before diesel, the thick black coal smoke and steam from the engine would linger in the tunnel since there were no shafts to vent this noxious mix.

Despite the frequent track inspections, there were still delays inside the tunnel caused by rock falls. At times the brakemen and other train workers would have had to endure a prolonged stay inside the tunnel until the obstruction was cleared. Moreover, after laboring up the Shawangunk ridge from Summitville, sometimes with the help of a second pusher engine, a freight train would have had to pass through the tunnel at low speed. The reason for this is because the train might have to take on orders as it slowly passed the High View station less than 200 yards from the tunnel’s south portal. The train might even have to stop if such a signal to halt was displayed at the station’s signal tower.

For one reason or another, brakemen and other trainmen would have had to spend considerable time inside the tunnel amidst the engine’s toxic fumes. Before the advent of the enclosed cabin for the brakemen, they would ride on metal ladders on the sides or ends of the rail cars. Even after the brakemen’s cabin arrived on the scene in the 1880’s, the cabins were open to the elements so that the brakemen could hear the braking signals from the engineer sent forth from the train’s whistle. This made the arduous work of the brakemen even more daunting. (The situation was even worse for the front end trainmen like engineers and firemen who rode on an open platform at the rear of the smoke and steam spewing engine.) In the days before OSHA there was nothing to protect the health of these invaluable rail workers.

Besides the responsibilities of applying and releasing the train’s brakes, the brakeman also was responsible for coupling and uncoupling the train’s cars. In the days of link and pin coupling, switching cars was an inherently dangerous operation where the brakeman had to stand between two cars and attach or detach them. They risked being crushed during his operation or having arms or fingers maimed whilst lining up the basic link and pin mechanism then is use. The O&W Summitville depot and rail yard where the Port Jervis to Kingston line crossed the O&W Main Line was one place where the brakeman would have been called upon to switch cars. At local businesses the brakeman would also have had to work to pick up or deliver local freight cars.

Even after the advent of automatic signals, when a train had to stop on the tracks the rear brakeman would be called upon to display a flag during the day or red safety lantern at night some distance from the end of the train. Frequently they would stay with the signal until the train was ready to proceed. On single track lines, the front brakeman or other trainman would display the warning signal at some distance from the front of the train. In harsh weather, especially during winter, the health of the brakemen was at risk. In the dark of winter, frostbite and hypothermia were all too frequently in evidence.

Throwing manual switches along the rail line was also a responsibility that the brakemen frequently had. Running ahead of a moving train the head brakeman would have to open the switch before the engine arrived. At the rear of the train, the rear brakeman would have to leap from the train, close the switch and then race to catch up to the train and get on board again. Running alongside the tracks and crossing over the ballast to reach the train was not an easy job since the ballast had an uneven surface that made running over it difficult. Brakemen climbing aboard a moving train frequently sustained injuries when they slipped and fell from the train. In the worst cases, a brakeman could fall beneath the train’s wheels and be severely injured or even killed.

Perhaps the most remarkable and risky maneuver performed by the brakemen was a procedure called the “flying switch”. In this operation, the rear part of the train which was behind the cars to be shunted to a siding was decoupled. Then, whilst the remainder of the train proceeded forward, when the train approached the switch, the brakeman on the train decoupled the “orphan” cars just as the engineer eased back on the throttle. Once these cars were decoupled, the engineer sped up leaving a gap between the front section of the train and the cars to be shunted. After the engine and the cars attached behind it went over the siding switch, the brakeman on the ground threw it thereby sending the “orphaned” cars into the siding. All this required split-second timing. In order to accomplish this feat the brakemen had to be agile and skilled. When the maneuver was finished the train would back up and pick up the cars that had been behind the shunted cars. The result would be part of the train left behind on a siding without involving a second engine, moving the cars excessively or doing any complicated maneuvering.

The “flying switch” was very dangerous for the brakemen involved. Railroading liability case law is filled with lawsuits filed by widows of brakemen killed executing this operation. Whilst doing a “flying switch” many brakemen lost their balance and fell beneath the car wheels. The performance of this switch at grade-crossings also appears to have been especially hazardous to pedestrians attempting to cross the tracks after the head of the train had passed. In many cases pedestrians were unaware that the “orphan” cars were following a short distance behind and were struck as these cars went through the grade-crossing. For this reason, a number of states outlawed the use of the “flying switch” at grade-crossings.

Brakemen found it hard to get insurance policies given the injury prone nature of their work. The benevolent mutual insurance brotherhoods they set up to self-insure themselves were to become, in later years, the trainmen’s unions. In fact, in 1883 the Brotherhood of Railroad Trainmen was born in a D&H Canal Company caboose in Oneonta, NY. In the years before OSHA, lax safety rule enforcement by the railroads left the burden of protection on the trainmen, especially the brakemen. All too frequently rules were made to shield the railroad companies against lawsuits rather than to protect the health of their trainmen.

The 19th century saw the creation of great new industries across America. The railroad industry is just one example of this phenomenon. These new fields produced new jobs where there were none before. The benefits of this vast new job creation were tempered by the lack of sufficiently powerful health and safety standards. Our modern regulatory regime owes its existence to the rise of governmental oversight in the late 19th century. Whilst the price paid by brakemen and other rail workers may have been high, it finally resulted in governmental protections being put into place to secure safe working conditions. Programs like OSHA may have flaws, but their benefit to the health of industrial workers has been demonstrated over time and is undeniable.

The story of the railroad companies and their workers is really- the tale of the development and evolution of American industry in general. The pattern of American industry is one of a headlong rush of innovation culminating in an environment of excesses which was then tempered by a period of moderation. The rise of the rail empires in the later 19th century shows this unbridled progress and the impact of its excesses. The interlocking directorates of the railroads as well as the greed of the “Robber Barons” created an anti-competitive industry with little regard, in general, for its workers’ health and well-being. This was followed by government regulation of the industry with the creation of the Interstate Commerce Commission in 1887 and such acts as the Federal Railway Safety Appliance Act of 1893 which went into effect in 1898.

Later implementation of government work rules to protect railroad workers was also important in making their work life safer. In 1907 the Hours of Work Act was made Federal law and limited to 16 the number of hours a train crew could work continuously. After this period the railroad was required to grant the crew 10 hours off. Nevertheless, some legislation, such as the “full-crew” laws in force in 20 states in 1913, did not seem to have made the railroads safer for passengers or trainmen. Overall, however, rail workers benefited significantly from federal laws and regulations designed to improve their safety whilst on the job.

Copyright 2009 by Stephen Skye

Short Link: